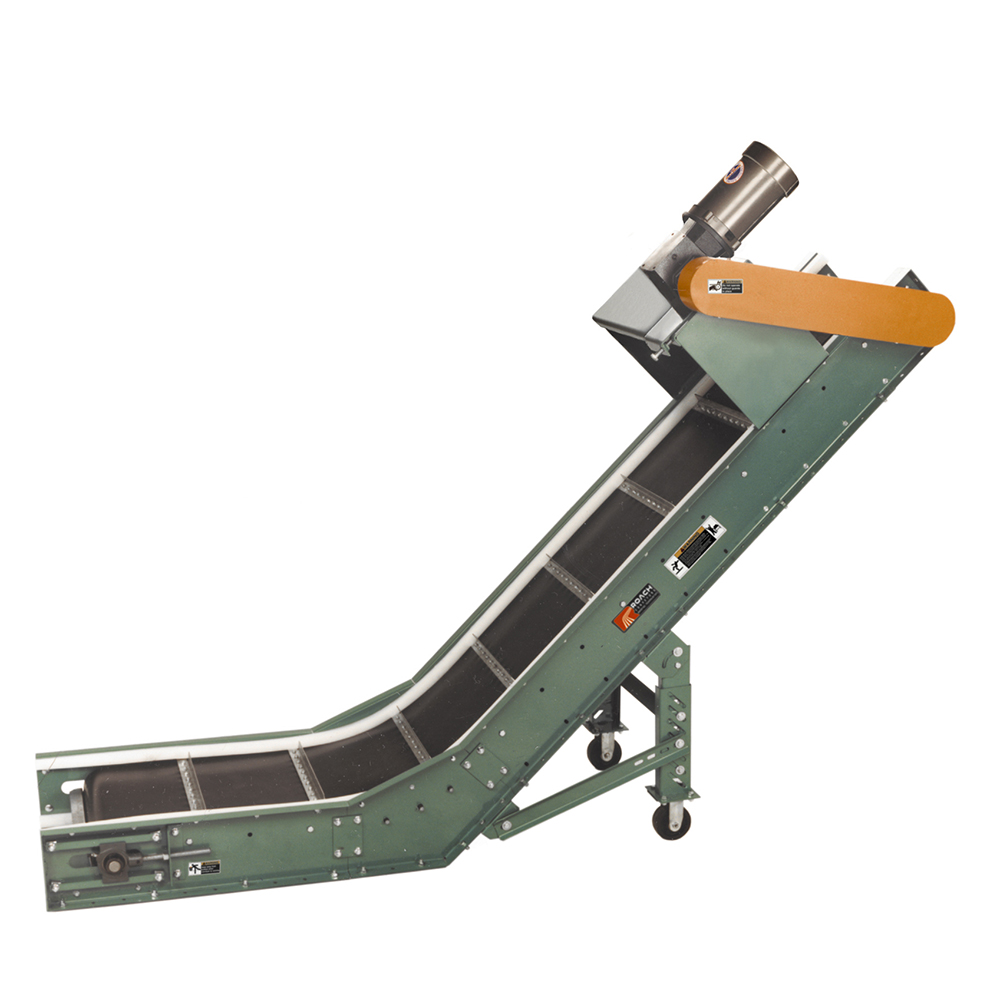

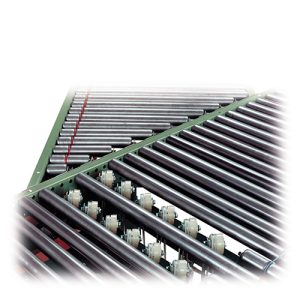

Parts conveyors are widely used to convey chips, slugs or scrap materials to hoppers or other containers for disposal or recycling. Model PC, at left is shown with nitrile belt. PC at right includes wire mesh belting. Each PC is supplied with flapper gate at infeed end and right hand drive.

PC-F | Parts Conveyor With Feeder

| Specifications | BELTING: 3-ply black nitrile belt or 1/2″ x 1″ flat wire mesh belt with 1-1/2″ high galvanized cleats on 12″ centers. DRIVE PULLEY: 4″ dia., with 1-3/16″ dia. shaft, fully lagged with nitrile belt; 4″ dia. sprockets supplied with flat wire mesh belt. TAIL PULLEY: 4″ dia. with 1-3/16″ dia. shaft. TAKE-UP: Screw type unit at tail pulley provides 12″ belt take-up. BED: 8″ deep x 12 ga. enclosed box type construction with 14 ga. steel belt return pan. BEARINGS: All pulley bearings are precision, heavy duty, lubricated, ball bearing units with cast iron housings. BELT SPEED: 35 FPM, constant. MINIMUM PARTS SIZE: 1/2″ cube for nitrile belt, 1″ cube for flat wire mesh belt. INCLINE: 30, 36 and 45 degree (specify). PORTABLE SUPPORT: Adjustable floor support with 4″ dia. casters and bracing. MOTOR DRIVE: 1/3 HP, 230/460/3, 60 cycle, ODP right angle gear motor. CAPACITY: 350 lbs. total distributed load. ROLLER CHAIN: No. 50 chain provided at drive pulley. Chain take-up provided on motor base. ELECTRICAL CONTROLS: Optional |

|---|

PC-F

Parts conveyors are widely used to convey chips, slugs or scrap materials to hoppers or other containers for disposal or recycling. Model PC, at left is shown with nitrile belt. PC at right includes wire mesh belting. Each PC is supplied with flapper gate at infeed end and right hand drive.

| Specifications | BELTING: 3-ply black nitrile belt or 1/2″ x 1″ flat wire mesh belt with 1-1/2″ high galvanized cleats on 12″ centers. DRIVE PULLEY: 4″ dia., with 1-3/16″ dia. shaft, fully lagged with nitrile belt; 4″ dia. sprockets supplied with flat wire mesh belt. TAIL PULLEY: 4″ dia. with 1-3/16″ dia. shaft. TAKE-UP: Screw type unit at tail pulley provides 12″ belt take-up. BED: 8″ deep x 12 ga. enclosed box type construction with 14 ga. steel belt return pan. BEARINGS: All pulley bearings are precision, heavy duty, lubricated, ball bearing units with cast iron housings. BELT SPEED: 35 FPM, constant. MINIMUM PARTS SIZE: 1/2″ cube for nitrile belt, 1″ cube for flat wire mesh belt. INCLINE: 30, 36 and 45 degree (specify). PORTABLE SUPPORT: Adjustable floor support with 4″ dia. casters and bracing. MOTOR DRIVE: 1/3 HP, 230/460/3, 60 cycle, ODP right angle gear motor. CAPACITY: 350 lbs. total distributed load. ROLLER CHAIN: No. 50 chain provided at drive pulley. Chain take-up provided on motor base. ELECTRICAL CONTROLS: Optional |

|---|

PC-F

Accumulation Conveyors(10)

Accumulation

Belt Conveyors(10)

Belt Conveyors

Belt Driven Live Roller(7)

Belt Driven Live Roller

Chain Drag(5)

Chain Driven Live Roller(11)

Chain Driven Live Roller

Flexible Conveyors(3)

Flexible Conveyors

Gravity Conveyors(19)

Gravity Conveyors

Line Shaft(9)

Line Shaft

MDZ | Motor Driven Zone Accumulator(2)

MDZ | Motor Driven Zone Accumulator

Parts Conveyor(3)

Parts Conveyor

Plastic Belt(9)

Plastic Belt

Powered Roller(14)

Powered Roller

Slat Conveyors(2)

Slat Conveyors

Transfers(8)

Transfers

Wire Mesh Belt(3)

Wire Mesh Belt

Glass & Solar Handling(8)

Glass & Solar Handling

Heavy Duty Conveyors(15)

Heavy Duty Conveyors

Laundry(11)

laundry

MDR | Motor Driven Roller Smart Conveyors(6)

MDR | Motor Driven Roller Smart Conveyors

Sortation Conveyors(7)

Sortation Conveyors

Special Transfers(11)

Special Transfers

Stackers | Destackers(2)

Stackers/Destackers

Stops | Barriers | Walkovers(10)

Stops | Barriers | Walkovers

Tabletop Chain Conveyors(5)

Tabletop Chain Conveyors

Transfer Carts(9)

Transfer Carts

Turntables(17)

Turntables

Upenders | Downenders | Rollovers(10)

Upenders | Downenders | Rollovers

Vertical Conveyors(8)

Vertical Conveyors

Wheel & Tire Conveyors(4)

Wheel & Tire Conveyors