Roach 251CALR is the choice to horizontally convey heavier unit loads where transfers, side loading or unloading is required. Its standard center drive allows for reversible operation.

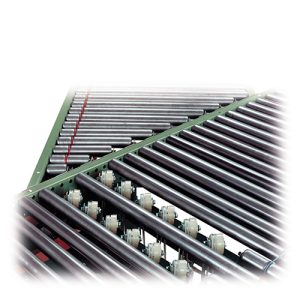

251CALR | Live Roller Cam Adjusted Heavy Duty Conveyor

| Specifications | TREAD ROLLERS: 2-1/2″ dia. x 11 ga. steel, model 251S. PRESSURE ROLLERS: 1.9″ dia. x 16 ga. steel, model 196S; same BF as conveyor up to 39″ BF; units 43″ BF and above, rollers are 21″ BF with BELTING: 12″ wide PVC-120. RETURN ROLLERS: 1.9″ dia. x 16 ga. steel, model 196S CENTER DRIVE: Reversible drive with 24″ integral belt take-up. For units under 8′-0″ overall length, drive components must be stacked. END PULLEY: 4″ dia. with 1-3/16″ dia. shaft on 15″-39″ BF; 6″ dia. with 1-7/16″ dia. shaft above 39″ BF; both crowned. DRIVE PULLEY: 8″ dia. with 1-7/16″ dia. shaft on 15″-39″ BF; 12″ dia. with 1-15/16″ dia. shaft above 39″ BF; both crowned and fully lagged. SPEED: 35 FPM, constant. BEARINGS: All pulley bearings are precision, heavy duty, lubricated, ball bearing units with cast iron housings. BED: 7″ x 1-1/2″ x 10 ga. formed steel channel frame slotted for tread rollers to pop-out. When unit is installed at 7′-0″ elevation or higher, rollers must be retained in conveyor frame. Specify desired elevation. Bed sections attached with couplings and floor supports. MOTOR DRIVE: 1 HP, 230/460/3, 60 cycle, ODP right angle gear motor. FLOOR SUPPORTS: 8″ and 12″ center drive (with 4″ or 6″end pulley) adjustable 33″ to 36″ TOR with SH-6 at end plates and SH-7 at intermediates. Supports provided on 5′ centers and should be lagged to floor. ROLLER CHAIN: Drive pulley is driven by No. 50 roller chain for 1-1/2 HP or less and No. 60 chain on larger drives. Chain take-up provided on motor base. ELECTRICAL CONTROLS: Optional |

|---|

251CALR

Roach 251CALR is the choice to horizontally convey heavier unit loads where transfers, side loading or unloading is required. Its standard center drive allows for reversible operation.

| Specifications | TREAD ROLLERS: 2-1/2″ dia. x 11 ga. steel, model 251S. PRESSURE ROLLERS: 1.9″ dia. x 16 ga. steel, model 196S; same BF as conveyor up to 39″ BF; units 43″ BF and above, rollers are 21″ BF with BELTING: 12″ wide PVC-120. RETURN ROLLERS: 1.9″ dia. x 16 ga. steel, model 196S CENTER DRIVE: Reversible drive with 24″ integral belt take-up. For units under 8′-0″ overall length, drive components must be stacked. END PULLEY: 4″ dia. with 1-3/16″ dia. shaft on 15″-39″ BF; 6″ dia. with 1-7/16″ dia. shaft above 39″ BF; both crowned. DRIVE PULLEY: 8″ dia. with 1-7/16″ dia. shaft on 15″-39″ BF; 12″ dia. with 1-15/16″ dia. shaft above 39″ BF; both crowned and fully lagged. SPEED: 35 FPM, constant. BEARINGS: All pulley bearings are precision, heavy duty, lubricated, ball bearing units with cast iron housings. BED: 7″ x 1-1/2″ x 10 ga. formed steel channel frame slotted for tread rollers to pop-out. When unit is installed at 7′-0″ elevation or higher, rollers must be retained in conveyor frame. Specify desired elevation. Bed sections attached with couplings and floor supports. MOTOR DRIVE: 1 HP, 230/460/3, 60 cycle, ODP right angle gear motor. FLOOR SUPPORTS: 8″ and 12″ center drive (with 4″ or 6″end pulley) adjustable 33″ to 36″ TOR with SH-6 at end plates and SH-7 at intermediates. Supports provided on 5′ centers and should be lagged to floor. ROLLER CHAIN: Drive pulley is driven by No. 50 roller chain for 1-1/2 HP or less and No. 60 chain on larger drives. Chain take-up provided on motor base. ELECTRICAL CONTROLS: Optional |

|---|

251CALR

Accumulation Conveyors(9)

Accumulation

Belt Conveyors(10)

Belt Conveyors

Belt Driven Live Roller(7)

Belt Driven Live Roller

Chain Drag(5)

Chain Driven Live Roller(11)

Chain Driven Live Roller

Flexible Conveyors(2)

Flexible Conveyors

Gravity Conveyors(19)

Gravity Conveyors

Line Shaft(9)

Line Shaft

MDZ | Motor Driven Zone Accumulator(2)

MDZ | Motor Driven Zone Accumulator

Parts Conveyor(3)

Parts Conveyor

Plastic Belt(9)

Plastic Belt

Powered Roller(13)

Powered Roller

Slat Conveyors(2)

Slat Conveyors

Transfers(8)

Transfers

Wire Mesh Belt(3)

Wire Mesh Belt

Glass & Solar Handling(8)

Glass & Solar Handling

Heavy Duty Conveyors(15)

Heavy Duty Conveyors

Laundry(11)

laundry

MDR | Motor Driven Roller Smart Conveyors(6)

MDR | Motor Driven Roller Smart Conveyors

Sortation Conveyors(7)

Sortation Conveyors

Special Transfers(11)

Special Transfers

Stackers | Destackers(2)

Stackers/Destackers

Stops | Barriers | Walkovers(10)

Stops | Barriers | Walkovers

Tabletop Chain Conveyors(5)

Tabletop Chain Conveyors

Transfer Carts(9)

Transfer Carts

Turntables(17)

Turntables

Upenders | Downenders | Rollovers(10)

Upenders | Downenders | Rollovers

Vertical Conveyors(8)

Vertical Conveyors

Wheel & Tire Conveyors(4)

Wheel & Tire Conveyors